Latest Products

Home

-

Sale!

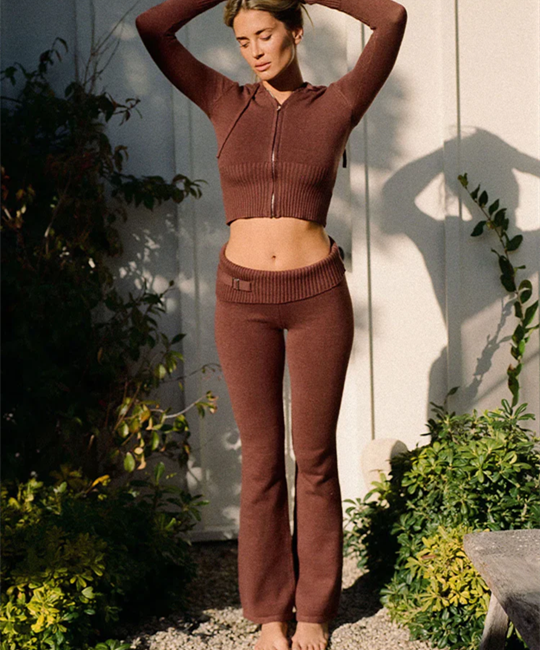

Womens Bottoms | Frankies Bikinis Astrid Low Rise Flare Legging Creme Brulee

$ 153.00$ 84.00 Select options -

Sale!

Womens One Pieces | Frankies Bikinis Etta Shine Cheeky One Piece Swimsuit Candied Violet

$ 144.50$ 84.00 Select options -

Sale!

Womens Loungewear & Knits | Frankies Bikinis Jasmine Embroidered Mini Short Sea Fairy

$ 204.00$ 84.00 Select options -

Sale!

Womens Dresses & Bodysuits | Frankies Bikinis Swift Tennis Dress Baby Blue

$ 172.80$ 71.00 Select options

Featured Products

-

Sale!

Womens Tops | Frankies Bikinis Etta Floral Bralette Bikini Top French Holiday

$ 172.80$ 71.00 Select options -

Sale!

Womens Dresses & Bodysuits | Frankies Bikinis Swift Tennis Dress Baby Pink

$ 152.50$ 60.00 Select options -

Sale!

Womens Bikinis | Frankies Bikinis Enzo Ribbed Cheeky Bikini Bottom Crimson

$ 170.00$ 67.00 Select options -

Sale!

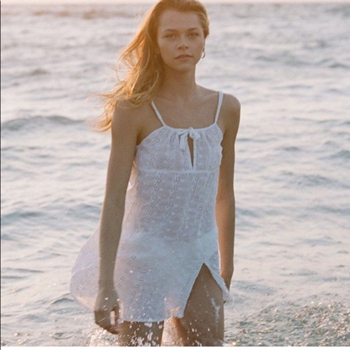

Womens Bikinis | Frankies Bikinis Pam Plissé Underwire Bikini Top Optic White

$ 127.50$ 84.00 Select options